المنتجات الساخنة

REDUCTION OF CO EMISSIONS IN CEMENT

网页2019年4月24日 EMISSIONS IN CEMENT PRODUCTION BY USING PREHEATER HAIYAN 1XIE1, PRANSHOO SOLANKI,ALIREZA MOJADAM1, and WENFANG LIU2 1Dept of Technology,Illinois State University, Normal USA 2School of Management,

Contact

CFD simulation of the preheater cyclone of a cement plant

网页2018年3月1日 In traditional cement manufacturing technology, the preheater system is positioned before the rotary kiln in order to increase the heat transfer between the raw

Contact

REDUCTION OF CO 2 EMISSIONS IN CEMENT PRODUCTION BY USING PREHEATER

网页2019年5月1日 This study suggests shifting from wet and dry kilns to preheater-precalciner systems to obtain the potential benefits of CO 2 emission reduction in the cement

Contact

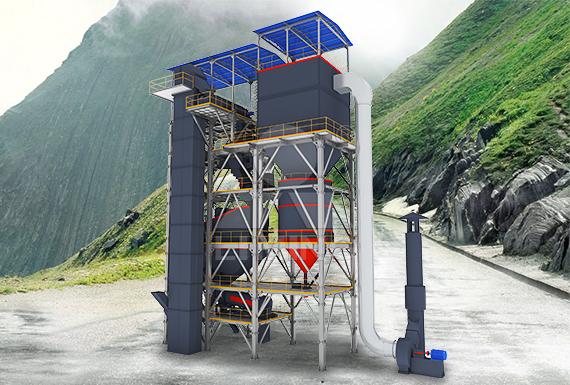

Preheater In Cement Plant, Cyclone Preheater, Cement Preheater

网页The cyclone preheater, also called cement preheater, suspension preheater, is a kind of preheater in cement plant.As the core equipment of dry method cement production line,

Contact

Everything you need to know about Preheaters

网页improving the thermal efficiency of the energy-intensive process of cement manufacturing. This chapter discusses the role of preheaters and precalciners in improved pyroprocessing and related material, operation,

Contact

Cement Manufacturing Institute for Transportation

网页2018年8月3日 Cement Manufacturing Process. CaO SiO 2 Al 2 O 3 Fe 2 O 3 MgO Loss Limestone (chalk) 52.0 5.7 0.8 0.3 0.4 40.4 General Diagram of Preheater Reactions.

Contact

Preheater In Cement Plant Cyclone Preheater

网页Cyclone preheater, also known as suspension preheater, is the main cement equipment commonly used in the new dry process cement production line. It is the main gas-solid reaction unit of the cement raw meal pre

Contact

Cement Plant Cyclone Preheater

网页AGICO Cement Preheater Features. Our cyclone preheater adopts a multi-stage circulation suspension preheating mode, and has a high production efficiency. The preheating temperature in the cyclone preheater can

Contact

Preheater Cyclone Thermal Efficiency Analysis

网页The 5-stage suspension preheater cyclone is the device inside which the cement raw meal performs heat exchange with hot gas from the rotary kiln and is preheated. It is one of the key equipment in the cement clinker

Contact

Role of Volatiles in Cement Manufacture and in the Use of Cement

网页1983年1月1日 Publisher Summary. In the manufacture of Portland cement clinker, the kiln feed and fuel contain some minor constituents that are volatile in nature. These are

Contact

Sustainable transition towards biomass-based cement

网页2022年7月1日 In cement manufacturing, process heating accounts for 70–80% of the total energy consumption, and electricity accounts for the rest (20–30%). The pyro-processing sections (precalciner and kiln) are the most thermal-intensive steps, with temperatures reaching 900–950 °C and 1350–1400 °C in the precalciner and rotary kiln respectively.

Contact

Digitization and the future of the cement plant McKinsey

网页2020年9月16日 According to our analyses, the cement plant of the future could reduce emissions by up to 75 percent by 2050 compared with 2017. Around 20 percent will come from operational advances, such as energy-efficiency measures and clinker substitution. An additional 10 percent will come from alternative fuels—however, the availability of

Contact

Precalcination in cement plants (system description and

网页2000年7月1日 In the present , the first steps towards introducing a systemic approach for the control of preca1cination in cement manufacturing, are made. The interaction between the precalciner and the other components of the pyroprocess (kiln, preheater and cooler) is described. The control design of the process is con figured

Contact

THE EFFECT OF INVENTORY MANAGEMENT ON

网页2021年3月31日 of Cement Manufacturing Companies in Nigeria’ is completely delivered by me by following the guideline of Dublin Business School (DBS) in the year 2020. Additionally, the information derived from the literature and respondents have been duly acknowledged in the

Contact

Cement Definition, Composition, Manufacture,

网页cement, in general, adhesive substances of all kinds, but, in a narrower sense, the binding materials used in building and civil engineering construction. Cements of this kind are finely ground powders that, when

Contact

A Review on Pyroprocessing Techniques for

网页2020年2月9日 From the discussion, it has been established that the cement manufacturing and grinding technologies are capital-intensive investments. The kiln processes are advanced and use both electricity

Contact

Health Risk and Environmental Assessment of Cement Production

网页2021年8月30日 The cement manufacturing industry has played a fundamental role in global economic development, but its production is a major facilitator to anthropogenic CO2 release and solid waste generation. Nigeria has the largest cement industry in West Africa, with an aggregate capacity of 58.9 million metric tonnes (MMT) per year. The Ministry for

Contact

Carbon-negative cement manufacturing from seawater

网页The cement industry is one of the largest sources of man-made carbon dioxide (CO 2) emissions and is a hard-to-decarbonize sector that represents a major roadblock to achieving global greenhouse gas emission reduction targets.To address this challenge, the present study demonstrates the key steps in an environmentally friendly process for the

Contact

Cement Sustainability Initiative (CSI) World Business

网页2017年1月9日 Cement Sustainability Initiative Introduction 3 Introduction Cement manufacturing is an energy- and resource-intensive process. Every year the cement industry produces over 1.8 billion tonnes of cement at plants in almost every country in the world. The way the industry selects and uses fuels and raw materials is an important factor in

Contact

Clinkerization an overview ScienceDirect Topics

网页Progress in the Adoption of Geopolymer Cement* J.S.J. Van Deventer, in Handbook of Low Carbon Concrete, 2017 10.7 Reduction in Carbon Emissions. CO 2 emissions from cement production are incurred through the consumption of fossil fuels, the use of electricity, and the chemical decomposition of limestone during clinkerization, which can take place at

Contact

Role of nanofillers for high mechanical performance

网页2022年3月7日 In the present study, a framework that connects molecular failure mechanics, microscale characterisation and engineering performance of cement with mineral nanofillers was established to quantify the roles of these nanofillers in cementitious composites. Three of the most widely used mineral nanofillers, namely nano-Fe 2 O 3,

Contact

1 Role of cement manufacturing in circular economy

网页In this , concrete mixtures were prepared with the substitution of CEM I 42.5R cement with an “untreated” raw bypass dust at the ratios of 10, 20, and 30% along with a control specimen

Contact

Cement Manufacturing using Alternative Fuels and the

网页2004年3月15日 Abstract. Energy costs and environmental standards encouraged cement manufacturers world-wide to evaluate to what extent conventional fuels can be replaced by alternative fuels, i.e., processed

Contact

Carbon-negative cement manufacturing from seawater

网页The cement industry is one of the largest sources of man-made carbon dioxide (CO 2) emissions and is a hard-to-decarbonize sector that represents a major roadblock to achieving global greenhouse gas emission reduction targets.To address this challenge, the present study demonstrates the key steps in an environmentally friendly process for the

Contact

Sustainability Free Full-Text Biochar-Added Cementitious

网页2021年8月20日 Cement manufacturing involves several processes; the production, processing, and preparation phases alone account for 7% of total global CO 2 emissions . China is the world’s leading cement producer, accounting for half of global cement production; it is no surprise that China reported 823 million metric tonnes of CO 2

Contact

A perspective on environmental sustainability in the cement

网页2020年7月14日 Cement production is a major contributor to anthropogenic CO2 emissions and solid waste generation. This stone discusses some of the key issues as regards the slow progress in achieving environmental sustainability in the cement industry. Techniques such as carbon capture and storage (CCS), material substitution, alternative fuels and

Contact

Cement and Concrete

网页CementConcrete. In its simplest form, concrete is a mixture of paste and aggregates. The paste, composed of portland cement and water, coats the surface of the fine and coarse aggregates. Through a chemical reaction called hydration, the paste hardens and gains strength to form the rock-like mass known as concrete.

Contact

ROLE OF MINOR ELEMENTS IN CEMENT MANUFACTURE AND

网页The purpose of this review is to collect pertinent information on the behavior of minor and trace elements on the manufacture and use of cement. Attempts have been made to identify gaps, if any, in the information thus far available and suggest work for further investigations. As cement manufacturers continually strive to conserve resources

Contact

Cement Industry an overview ScienceDirect Topics

网页The cement industry is the most important consumer of rubber waste. It uses 236,000 t of scrap tires (26 MJ/kg calorific heat) and 290,000 t of industrial waste (plastic waste, , textiles, etc., 22 MJ/kg caloric heat) (VDZ, 1999 ). Table VI.5.21 shows a comparison of components of traditional fuels and scrap tires.

Contact

Role of binary cement including Supplementary

网页2017年12月1日 The cement sector improved its CCA performance by 44.8% between 1990 and 2010 which exceeds the agreed target of 30%. The Ground Granulated Blast furnace Slag (GGBS), sector achieved a 16% energy reduction between 1999 and 2010 by improving the process of grinding. 2. Binary cement in concrete manufacturing using GGBS

Contact