المنتجات الساخنة

The performance improvement of a full-scale autogenous mill by setting

网页2020年10月20日 In comparison to conventional tumbling mills, i.e., rod- and ball mills, the grinding media in an AG mill derive from the feed ore itself (Gupta and Yan, 2016; Hahne

Contact

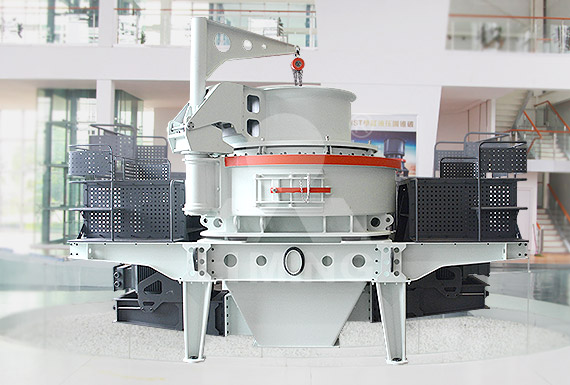

Autogenous mill, Ag Mill, Semi-autogenous Mill, Ball Mill

网页Autogenous Mill. [Introduction] : A wet autogenous grinding mill that materials as grinding media. [Capacity] : 200-350mm. [Improvement] : High-efficiency autogenous mill can

Contact

AG Autogenous Grinding 911 Metallurgist

网页2015年8月6日 In conventional mills the diameter of the mill is smaller than its length. In autogenous mills the diameter is greater than the length.

Contact

Autogenous Mill Efficient AG Mill For Sale AGICO Autogenous

网页The autogenous mill can process materials of any property, especially when grinding asbestos, iron ore, copper ore, limestone, gold ore, manganese ore, etc. It has a large

Contact

Autogenous GrindingSemi Autogenous

网页2017年7月20日 Autogenous grinding is favored when the ore is quite competent and a fine grind is required. Semi-autogenous grinding is applied when fine crushing could cause severe problems or when ore is variable

Contact

RoM BALL MILLS A COMPARISON WITH AG/SAG

网页RoM Ball mills, like SAG mills, utilise coarse rocks in the RoM feed as grinding media but with 25 40% steel balls added, which is advantageous when the coarse fraction in the

Contact

Dynamic modelling and simulation of semi-autogenous mills

网页2009年1月1日 The mass of grinding media inside the chamber is determined by a mass balance considering the ball replacement rate and the metal consumption rate, this latter

Contact

Ball Mill VS Autogenous Mill Xinhai Xinhai Mining

网页2019年11月11日 The ball mill can grind the ore to a finer particle size, but the range of the feed particle size is also higher, and the cost of grinding is higher, so it is usually

Contact

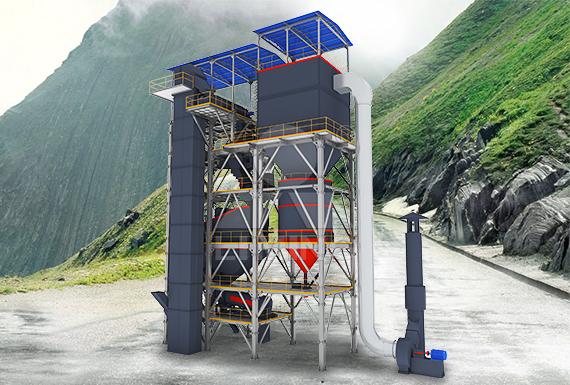

Semi Autogenous Mill SAG Mills For Sale AGICO Ball Mill

网页The semi-autogenous mill is a new type of grinding equipment with both crushing and grinding functions. It has the advantages of simple process flow, small investment, short

Contact

Semi Autogenous Grinding Mill an overview ScienceDirect

网页In a SAG mill the dimensions of the mill were 9.75. m × 3.5 m and the specific gravities of the mineral and that of the balls charged were 4.1 and 7.9 respectively.. The mill was rotated at 75% of its critical speed when 8 % of the mill volume was charged with grinding balls.Estimate:1. The mill power drawn, 2. The maximum mill filling possible.

Contact

Autogenous Mill SpringerLink

网页2023年6月7日 The autogenous mill will grind the material to the extent that the content of the particles with particle size <0.074 mm accounts for 20–50% of total quantity of product, and crushing ratio is 4000–5000, which is over 10 times that of ball mill and rod mill.

Contact

Autogenous Mill Efficient AG Mill For Sale AGICO Autogenous

网页The autogenous mill can process materials of any property, especially when grinding asbestos, iron ore, copper ore, limestone, gold ore, manganese ore, etc. It has a large grinding ratio, up to 4000-5000, and the feeding size is

Contact

RoM BALL MILLS A COMPARISON WITH AG/SAG

网页RoM Ball mills, like SAG mills, utilise coarse rocks in the RoM feed as grinding media but with 25 40% steel balls added, which is advantageous when the coarse fraction in the RoM feed is

Contact

Autogenous mills, semi-autogenous mills and ball mills

网页2017年7月29日 supported grinding mills up to the largest sizes. SAG/ball mill circuit incorporating pebble crushers and a POLYCOM® high-pressure grinding roll. SAG and ball mill for gold ore grinding. One of three SAG mills with 9.75 m diameter and 2 x 4000 kW drive power. These mills operate in conjunction with ball mills for iron ore grinding in Iran.

Contact

CALCULATION OF THE REQUIRED SEMIAUTOGENOUS

网页2016年1月10日 primary wet autogenous mill (WAM) and a series of ball mills. WAM is customary chosen either based on examination of analogous equipment specifications, or from the evidence of very expensive commercial and semicommercial testing that requires large sampling, much time and high investment [1]. The current practice of exploratory

Contact

Mill Charge an overview ScienceDirect Topics

网页Autogenous and Semi-Autogenous Mills. In Mineral Processing Design and Operations (Second Edition), 2016. 9.3.4 Mill Speed. During normal operation the mill speed tends to vary with mill charge.According to available literature, the operating speeds of AG mills are much higher than conventional tumbling mills and are in the range of 80–85% of the

Contact

The performance improvement of a full-scale autogenous mill by setting

网页2020年10月20日 In comparison to conventional tumbling mills, i.e., rod- and ball mills, the grinding media in an AG mill derive from the feed ore itself (Gupta and Yan, 2016; Hahne et al., 2003). Any change in the feed ore properties will therefore affect the grinding charge and thus, the AG mill performance (Bueno et al., 2013; Hahne et al., 2003; Mainza and

Contact

Slurry flow in mills: grate-only discharge mechanism (Part-1)

网页2003年7月1日 Discharge grates play an important role in determining the performance of autogenous, semi-autogenous and grate discharge ball mills. The flow capacity (grinding capacity) of these mills is strongly influenced by the discharge grate design––open area and position of apertures, as well as the performance of the pulp lifters.

Contact

Determination of lifter design, speed and filling effects in AG mills

网页2004年11月1日 The discrete element code, Particle Flow Code 3D (PFC3D), has been used in this work to model the effects of lifter height (5–25 cm) and mill speed (50–90% of critical) on the power draw and frequency distribution of specific energy (J/kg) of normal impacts in a 5 m diameter autogenous (AG) mill. It was found that the distribution of the

Contact

What is autogenous milling? Studybuff

网页2019年11月13日 SAG mills are autogenous mills that also use grinding balls like a ball mill. A SAG mill is usually a primary or first stage grinder. SAG mills use a ball charge of 8 to 21%. A Ball Mill grinds material by rotating a cylinder with steel grinding balls, causing the balls to fall back into the cylinder and onto the material to be ground.

Contact

Slurry flow in mills: grate-only discharge mechanism (Part-1)

网页2003年7月1日 Discharge grates play an important role in determining the performance of autogenous, semi-autogenous and grate discharge ball mills. The flow capacity (grinding capacity) of these mills is strongly influenced by the discharge grate design––open area and position of apertures, as well as the performance of the pulp lifters.

Contact

What’s the Difference Between SAG Mill and Ball Mill

网页2019年11月26日 The biggest characteristic of the sag mill is that the crushing ratio is large. The particle size of the materials to be ground is 300 ~ 400mm, sometimes even larger, and the minimum particle size of the

Contact

(PDF) Design of a typical Autogenous Mill: Part-II

网页2013年12月23日 An Autogenous Milling defined as used in this study, the term Autogenous milling means a process in which the size of the constituent pieces of a supply of rock is reduced in a tumbling mill

Contact

Mill Speed an overview ScienceDirect Topics

网页Autogenous and Semi-Autogenous Mills. In Mineral Processing Design and Operations (Second Edition), 2016. 9.3.4 Mill Speed. During normal operation the mill speed tends to vary with mill charge. According to available literature, the operating speeds of AG mills are much higher than conventional tumbling mills and are in the range of 80–85% of the

Contact

SAG Mill Liner Design PDF Mill (Grinding) Steel

网页2020年8月17日 Three-piece “compression-type” liner bolt sealer is designed to prevent leakage of slurry. or dust from mill liner bolt holes. Used in conjunction with Grade 5 (high-strength) bolts, this assembly is

Contact

(PDF) Design of a typical Autogenous Mill: Part-I

网页2013年12月23日 An Autogenous Milling defined as used in this study, the term Autogenous milling means a process in which the size of the constituent pieces of a supply of rock is reduced in a tumbling mill

Contact

Autogenous Grinding Mining Fundamentals

网页Autogenous grinding is a process of grinding ore in a rotating cylinder, using large pieces of the same ore. Autogenous mills operate mechanically like ball mills; however, the media used for grinding differs. Simply put, in autogenous grinding, the media is also the material that is being ground, whereas in other milling methods steel or

Contact

Ball Mill an overview ScienceDirect Topics

网页where d b.max is the maximum size of feed (mm); σ is compression strength (MPa); E is modulus of elasticity (MPa); ρb is density of material of balls (kg/m 3); D is inner diameter of the mill body (m).. Generally, a maximum allowed ball size is situated in the range from D /18 to D/24.. The degree of filling the mill with balls also influences productivity of the mill

Contact