المنتجات الساخنة

World Cement GrindingMilling Q&A World Cement

网页2022年2月18日 Along with the increasing demand for low clinker cements or high early strength cement types, the installation of the polysius ® booster mill is a highly energy-efficient solution for achieving the necessary cement quality even at existing cement

Contact

Cement grinding optimisation ScienceDirect

网页2004年11月1日 Due to limitation of the mill’s rotational speed, the smallest ball size is usually restricted to about 15 mm. Cement grinding using stirred mills (Pilevneli and

Contact

Cement Mill Cement Ball Mill Vertical Cement

网页In general, cement mill can both apply for dry cement production and wet cement production. Commonly, there are three hot types of cement mill in the cement industry: cement ball mill, Raymond mill, and vertical cement

Contact

Energy efficient cement ball mill from

网页Key benefits. High reliability over a century of experience with 4000+ ball mills installed globally. Large through-flow area ensures low pressure drop across the mill. Horizontal slide shoe bearing design allows much simpler

Contact

Cement Lafarge

网页2 天之前 Click below to learn more about our products: Portland Cement. Blended Cement. Supplementary Cementitious Materials. Specialty Products. Eastern Canada. 6509 Airport Road. Mississauga, ON, L4V

Contact

Cement Mill Cement Grinding Machine AGICO Cement Grinding Mill

网页Coal mill is the main equipment in the pulverized coal preparation process.Because calcining top-grade cement clinker requires a stable supply of coal powder as the fuel of cement

Contact

Cement Mill Dal Technic Machinery A Company

网页UDCM type mills are designed to achieve maximum grinding efficiency, low energy consumption, compact plant layout and compact mill drive design. All mill types may operate in either open or closed circuit. UDCM with its

Contact

How many types of cement mills are there? ball mills supplier

网页Cement milling is an essential process in the manufacturing of cement. There are several types of cement mills that are used in the milling process, including ball mills, vertical

Contact

Cement type composite panels manufactured using stone mill

网页2017年7月1日 Also the effect of sludge type in consequence of waste water treatment technique on properties of WCBs was investigated. 2. Experimental2.1. Materials.

Contact

Coal utilisation in the cement and concrete industries

网页2013年1月1日 The mill itself will likewise be designed to handle a maximum physical size which varies from mill type to mill type. For example, in the case of Vertical Spindle (Roller) type mills, the top size typically ranges from 25 to 50 mm (1–2 in.) depending on the mill geometry and rolling element size. Typically, the limitation is 5% of the

Contact

Cement Mill Dal Technic Machinery A Company

网页UDCM type mills are designed to achieve maximum grinding efficiency, low energy consumption, compact plant layout and compact mill drive design. All mill types may operate in either open or closed circuit. UDCM with its

Contact

Cement Mill Cement Ball Mill Vertical Cement

网页In general, cement mill can both apply for dry cement production and wet cement production. Commonly, there are three hot types of cement mill in the cement industry: cement ball mill, Raymond mill, and vertical cement

Contact

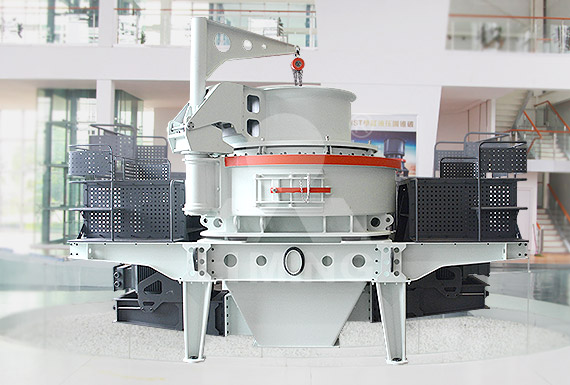

Simple Ore Extraction: Choose A Wholesale types mill cement

网页Do you need a new types mill cement for your mining operations? If so, Alibaba has plenty of possibilities. Gold ball mills are one option in Alibaba's mine mill catalog. These mills use ball-type grinders inside chambers. They offer extremely high efficiency levels when grinding rocks containing gold, with minimal friction and relatively low

Contact

DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR

网页2019年4月21日 software and to use in the further designs of ball mills. 1.1 FLS UMS Type Cement Ball Mill In 1893 (FLS) firm acquired the rights to a new mill type, the tube mill, from the French/Danish inventor. After being thoroughly redesigned and refined, the tube mill influenced the cement industry in the coming century. Fredrik

Contact

How many types of cement mills are there? ball mills supplier

网页Cement milling is an essential process in the manufacturing of cement. There are several types of cement mills that are used in the milling process, including ball mills, vertical roller mills, roller presses, and horizontal ring roller mills. Each type of cement mill has its unique characteristics that make it suitable for a particular purpose.

Contact

How to choose proper grinding media for your

网页2021年2月24日 1. Steel Balls. Steel balls are one of the most widely used grinding media in cement ball mills, their diameters can range from 20mm to 120mm according to different grinding requirements. In a cement ball

Contact

mill/sbm types of cement ball mill.md at main crush2022/mill

网页Contribute to crush2022/mill development by creating an account on GitHub.

Contact

Cement grinding optimisation ScienceDirect

网页2004年11月1日 Due to limitation of the mill’s rotational speed, the smallest ball size is usually restricted to about 15 mm. Cement grinding using stirred mills (Pilevneli and Azizli, 1999) indicates that using smaller media (5–8 mm range) improves grinding energy efficiency up to 50% using stirred mills. For specialized types of cement, which are finer

Contact

Raw Mill, Cement Raw Mill, Raw Mill In Cement

网页cement ball mill. Application: limestone, clay, coal, feldspar, calcite, talc, iron ore, copper, phosphate, graphite, quartz, slag. Capacity: 0.65-615T/H. The cement ball mill usually can be applied to raw meal grinding or cement

Contact

Cement Mill Price, 2023 Cement Mill Price Made-in

网页High Efficiency Wet and Dry Type Cement Ball Mill with Factory Price, Mining Grinding Machine . US$ 8000-38000 / Set. 1 Set (MOQ) Type : Ball Mill; Motor Type : DC Motor; Motor Power : 22-2300kw; Rotationl Speed

Contact

Roller Press KHD Humboldt Wedag

网页Simply put, the roller press is the most energy-efficient grinding machine on the market. Since its commercial introduction into the cement industry by KHD in the 1980s, hundreds of them have been installed in the cement

Contact

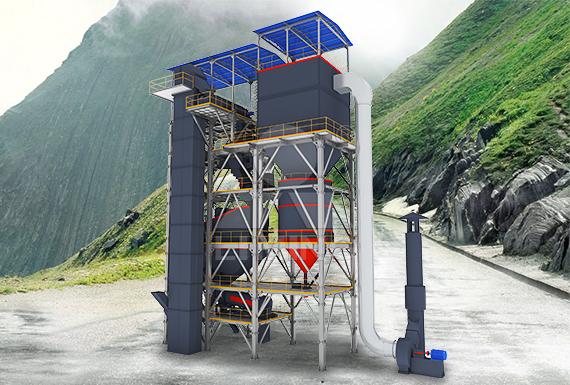

Cement Grinding Unit Cement Grinding Plant Cement

网页Cement grinding unit cost. Take the annual output of 600,000 tons of large-scale cement grinding station as an example, there are three common options can be recommended: SCHEME 1: roller press + φ 3.2 ×13m ball mill; SCHEME 2: φ 3.8 ×13m closed mill; SCHEME 3: clinker fine crusher + cement roller press+φ 3.2 ×13m ball mill.

Contact

Sustainable cement production—present and future

网页2011年7月1日 Ball mills have been used for over 100 years for milling processes in cement production. This mill type has prevailed because of its reliability and the favorable properties of the cement ground with ball mills. Primary ball mills were operated as open-circuit mills, later, separators were added to produce improved cement qualities in a closed

Contact

Cements ground in the vertical roller mill fulfil the

网页2013年3月1日 This study investigated a mathematical model for an industrial-scale vertical roller mill(VRM) at the Ilam Cement Plant in Iran. The model was calibrated using the initial survey's data, and the

Contact

Ball Mill an overview ScienceDirect Topics

网页Quantum Nanostructures (QDs): An Overview. D. Sumanth Kumar, H.M. Mahesh, in Synthesis of Inorganic Nanomaterials, 2018 3.6.1.1 Ball Milling. A ball mill is a type of grinder used to grind and blend bulk material into QDs/nanosize using different sized balls. The working principle is simple; impact and attrition size reduction take place as the ball

Contact

Cement Plants located in Myanmar The Global Cement Report

网页Cement plant locations and information on Myanmar can be found below. For full access to the database, purchase The Global Cement Report™, 14th Edition. Purchase. Summary. Cement capacity (Mt) Integrated plants. 17. Clinker plants. 0.

Contact

Cement manufacturing process: Step-by-step guide

网页2020年7月20日 Step 3: Grinding,homogenization and Clinkerization. Next in cement manufacturing process, the crushed rock is combined with other ingredients such as iron ore or fly ash and ground, mixed, and fed to a

Contact

Portland types I, II, III, IL Argos USA Cement and Ready

网页To aid you in fulfilling all of your specification and submittal needs, we have provided our certificates of compliance, monthly mill certificates, LEED letters, and safety data sheets for our cement products below. If you need technical data that is not included here, please contact our technical team. Portland Types I, II, III.

Contact

Roller mills INFINITY FOR CEMENT EQUIPMENT

网页Raymond bowl type ring mill. The Raymond bowl type ring mill [148] for coal drying-grinding is widely used in the American cement industry. This mill has all the characteristic features of the roller mills described above; it

Contact